Several steps that needed to pay special attention in the process of fiber fusion splicing

In many fiber fusion instances, we've found that making seemingly simple decisions can actually affect the performance of fiber transmission. Let me take a look at the process of fiber fusion.

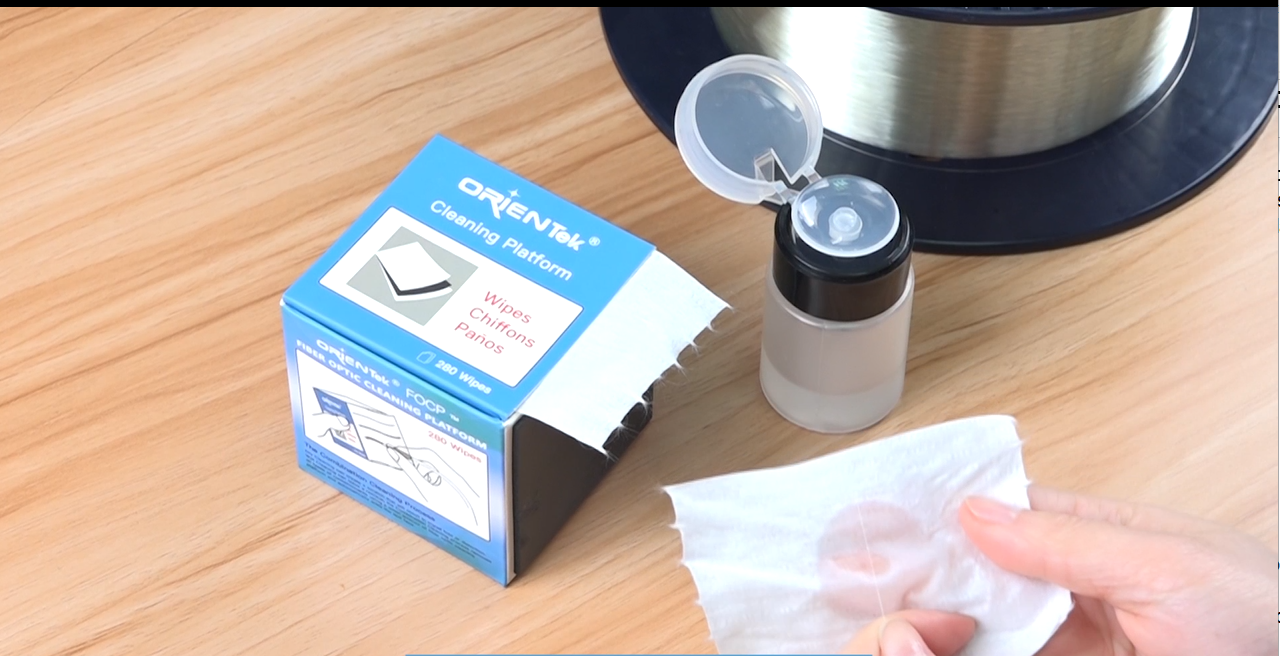

- Clean the fiber

Before fiber splicing, it is very important to clean the bare fiber after stripping, which can remove the residual particles and other possible pollutants in the stripping process. However, if the cleaning is not in place, it will bring a lot of trouble to splice and lead to greater splicing loss.

When cleaning bare optical fibers, operators are recommended to use fast volatile, non-flammable precision cleaning fluids. The cleaning fluid is sealed, a non - refillable container packed to prevent cross-contamination

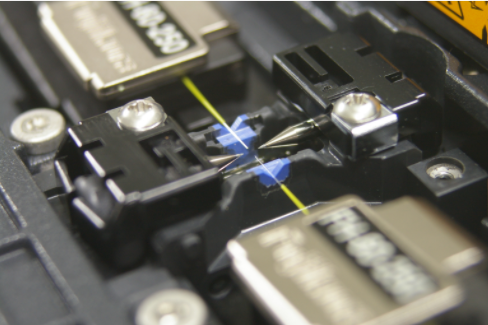

2.Using high precision cutting tools

Whether the end face of fiber is smooth or not has an important influence on the performance of the fusible or terminated fiber. In the past, people used to cut the optical fiber manually

with a fiber cutter. And now, automatic cutting tools make sure that the fiber end face is qualified.

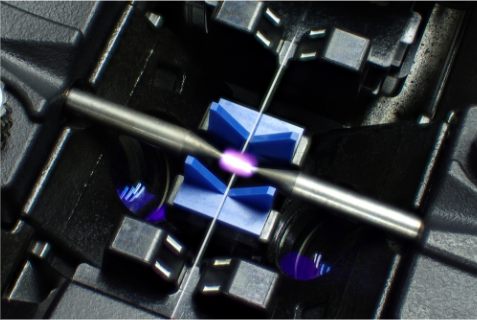

3.Calibration prior to fiber fusion

Keeping the fiber-optic splitters, cutting tools, and v-slots clean, the electrodes don't accumulate calcium, but many experienced operators find that sometimes they don't get the splicing results they want as the glass material is not perfect and the electrodes are not clean

4.Using new wipes/cloths

Avoid reusing lint-free wipes/paper because when a connector is cleaned with a piece of wipes/cloth, the wipes/cloth will become dirty and will get on your hands with the oil and ash layer. If you use it to clean other connectors, it will contaminate other connectors.

5. Inspect and clean connector ends before installation

The connector end face is easy to be polluted by dust and oil, so when we install the connector, we should check and clean it.

In summary, as long as you strictly follow the standard procedures, you can avoid these problems, and can greatly save future inspection and maintenance costs.

TheFO.com is your online source for all things fiber optic. We are a professional supplier of Fusion Splicing, OTDRs, Test Equipment, Tools & Kits, Cleaning Products and so on.