-

Fiber Optic Fusion Splicers and How They use and maintenance

Categories: Fusion SplicingGenerally speaking, the working environment in the field is poor, so the usual maintenance of the fusion splicer very important to the splicing effect and service life. As a special precision instrument, the fusion splicer should avoid excessive vibration as much as possible, and also be waterproof and moisture-proof. Desiccant can be placed in the case and placed in a dry and ventilated place when not in use.

In addition, do the following:

1) Keep the mirror surface of the lens and the mirror inside the windshield clean. If there are stains, use a cotton swab to wipe in one direction.

2) Keep the V-groove clean and wipe it with an alcohol stick.

3) Keep the fiber holder clean, seal it when pressing it, and wipe it with an alcohol stick.

4) Pay attention to the sensitivity of the windshield.

5) After preparing for fusion splicing and inserting the optical fiber, please do not open the windshield to prevent dust from entering, and do no

-

Tips that needed to pay special attention in the process of fiber fusion splicing

Categories: Fusion SplicingSeveral steps that needed to pay special attention in the process of fiber fusion splicing

In many fiber fusion instances, we've found that making seemingly simple decisions can actually affect the performance of fiber transmission. Let me take a look at the process of fiber fusion.

- Clean the fiber

Before fiber splicing, it is very important to clean the bare fiber after stripping, which can remove the residual particles and other possible pollutants in the stripping process. However, if the cleaning is not in place, it will bring a lot of trouble to splice and lead to greater splicing loss.

When cleaning bare optical fibers, operators are recommended to use fast volatile, non-flammable precision cleaning fluids. The cleaning fluid is sealed, a non

-

How to choose a suitable and convenient optical fiber identifier?

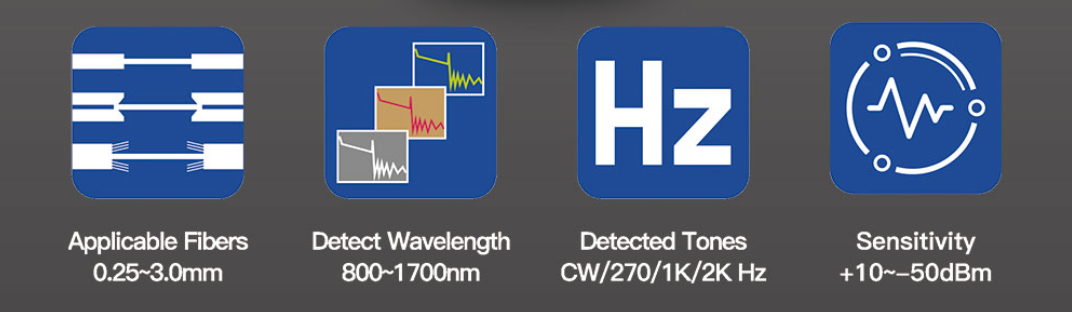

Categories: optical fiber identifierOptical fiber identifier is essential in optical cable engineering, such as maintenance, installation, and wiring. It can find and separate a specific fiber under the detection situation of any position of single-mode and multi-mode fiber, and use the recognizer to identify it on the line.

How to choose a suitable and convenient optical fiber identifier?Refer to the following aspects:

Convenience of testing、detectable range、monitor and so on.

ORIENTEK's latest generation of optical fiber identifier TFI-40, has a signal detection function with leading sensitivity, which can accurately locate the optical fiber in use, allowing users to easily detect optic

-

New Generation of Splicing is Coming-T44 FTTH Fusion Splicer

Categories: Fusion SplicingAs one of the advanced fiber-core optical fiber fusion splicers, T44 inherits the previous high-quality performance, and built-in the new discharge calibration technology raises the product to a very high level.

T44 has the following advantages:

- Real-time discharge calibration

Through the discharge calibration technology, more fine adjustment of fusing . So that the operation is not affected by harsh environment or technology, and maintain high quality. Effectively avoid repeated operations caused by improper pre-processing.

- Average Loss under 0.01dB

Based on our continuous research and development of ultra-low loss fiber, the T44 splice loss is only 0.01dB.

- Independent displa