Frequently noticed problems during operation

1. Clean, the inside and outside of the fiber fusion splicer, the fiber itself, the important parts are the V-groove, fiber presser foot and reflective lens.

2. When cutting, ensure that the cutting end face is 89°±1°, which is approximately vertical. During the process of placing the cut optical fiber at the specified position, the end face of the optical fiber should not touch any place. If it encounters it, we need to clean and cut again: emphasize Clean first and then cut!

3. When placing the fiber in its position, don't be too far or too close, 1/2 place, proficiency!

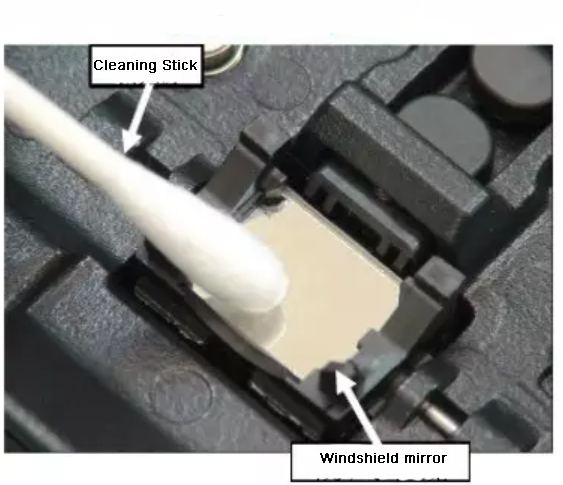

4. During the whole process of welding, do not open the windshield cover

5. Heating the heat-shrinkable tube is called the reinforcement of the splicing part. When heating, the fiber fusion splicing part must be placed in the middle, and a certain tension is applied to prevent bubbles and insufficient fixation during the heating process. The heating process and the fusion splicing process of the optical fiber can be carried out at the same time. When taking it out after heating, avoid touching the heated part to prevent safety accidents.

6. When arranging tools, pay attention to breaking the fiber head to prevent danger. The fiber is glass fiber, which is very thin and hard.

General daily maintenance

1. Clean and dry (Do not place in a humid environment with high temperature

2. Cleaning tools: cotton, cotton swab stick, air bag, alcohol, etc.

3. Parts that need to be cleaned:

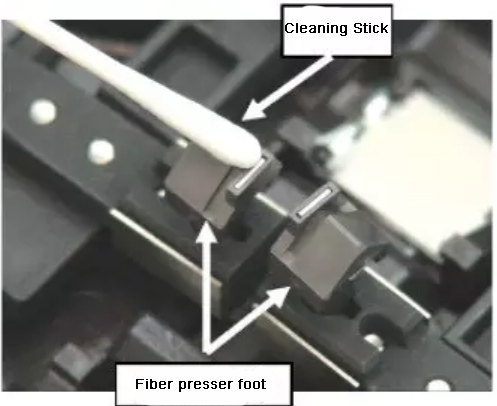

1) Optical fiber presser foot: wipe with a cotton swab dipped in alcohol in the same direction

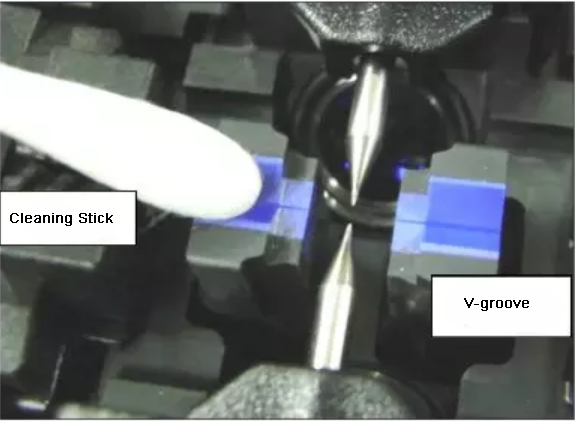

2) V-groove: Orientek has special cleaning tools. If not, you can use an alcohol stick or bare fiber to clean. Generally, air balloons are used to blow air instead of mouth blowing.

The upper and lower driving range of the fusion splicer's core adjustment direction is only tens of microns, and a slight foreign matter will cause the fiber image to deviate from the normal position, resulting in abnormal alignment. At this time, the V-shaped groove should be cleaned in time.

Process

1. Lift the windshield of the welding machine.

2. Open the fiber indenter and clamper plate.

3. Use a cotton swab stick with absolute alcohol (or sharpen a toothpick) to wipe the V-shaped groove in one direction.

Note: It is forbidden to clean the V-shaped groove with hard objects or apply force on the V-shaped groove to avoid damaging the V-shaped groove or making the V-shaped groove inaccurate, causing the meter to not work normally.

The composition of the optical system: mirror protection sheet, LED lighting, CCD camera (clean with an alcohol stick)

3) Optical fiber cleaver, avoid objects touching the blade.