What is Fiber Optic Inspection?

Fiber Inspection is the practice of viewing the end face of a fiber optic connector by use of an optical microscope. The primary reason for fiber inspection is to ensure that the connectors are free of any defects, damage, or debris that would prevent sufficient transmission of light when mated with another connector. Industry standards such as IEC-61300-3-35 are commonly referenced when determining acceptance criteria for an acceptable fiber connector end face.

What are the Benefits of Inspecting Your Fiber End Faces?

1. reduced network downtime

2. reduced troubleshooting

3. optimized signal performance

4. prevention of network damage.

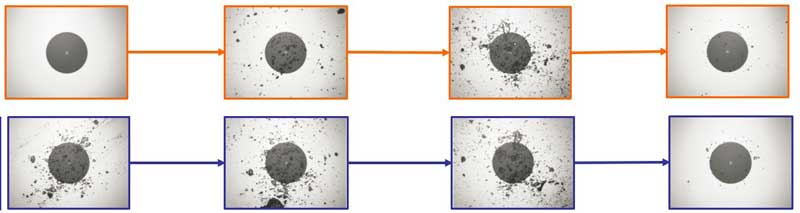

Sequence shows transfer from dirty connector (bottom) to clean (top) and damage from dirt due to mating (last photos) Photos from Sticklers

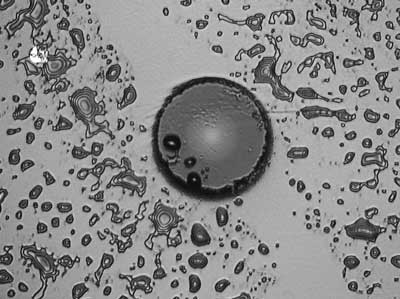

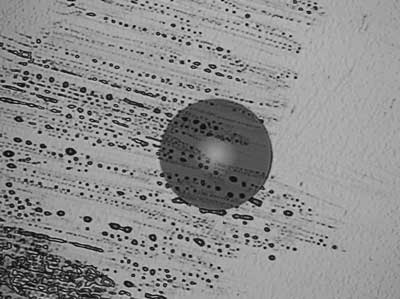

Here are some photos of connectors needing to be cleaned.

Connector with large amounts of surface dirt

Connector contaminated by oily residue

Connector smudged by oil on fingertip

Many connectors will have both dirt and residue on the ends that need cleaning. The type(s) of contamination and dirt will only be known if the connector is inspected visually.

Why is Fiber Inspection Important?

Contaminated or dirty fiber is the number-one cause of fiber optic network degradation, including permanent equipment damage. A single particle mated into the core of a fiber can cause significant back reflection, insertion loss and even equipment damage. Typical debris on a fiber connector endface can be 2 - 15µm and is only visible with a fiber optic probe microscope. Inspecting BOTH sides of the fiber connection is the ONLY WAY to ensure that it will be free of contamination and defects. Inspecting and cleaning connectors, test ports and reference cords before testing network connectors prevents cross-contamination.

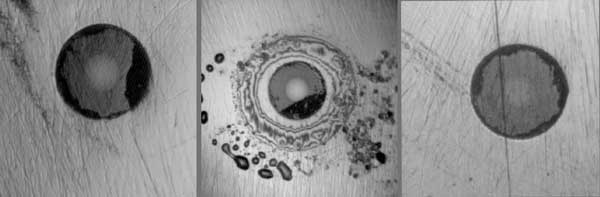

Microscope views of 3 bad connectors

As a result, proactive fiber optic inspection cleaning tools support the deployment of large-scale fiber optic network and fiber optic cabling initiatives and ensure reliable, high-quality delivery of high-speed, high-capacity, broadband services.

It is widely known in the fiber optic industry that scratches, defects, and dirt on fiber optic connector end faces negatively impact network performance. If dirty and damaged end faces are not dealt with systematically, these defects can degrade network performance and eventually take down an entire link. In the effort to guarantee a common level of performance from the connector, the IEC developed Standard 61300-3-35 which specifies pass/fail requirements for end face quality fiber inspection before connection.

To achieve its goal, OrienTek devoted many years to launching this device and after its debut, many customers left great comments, hoping it could be delivered to their country. Here is the collection and description of customers.

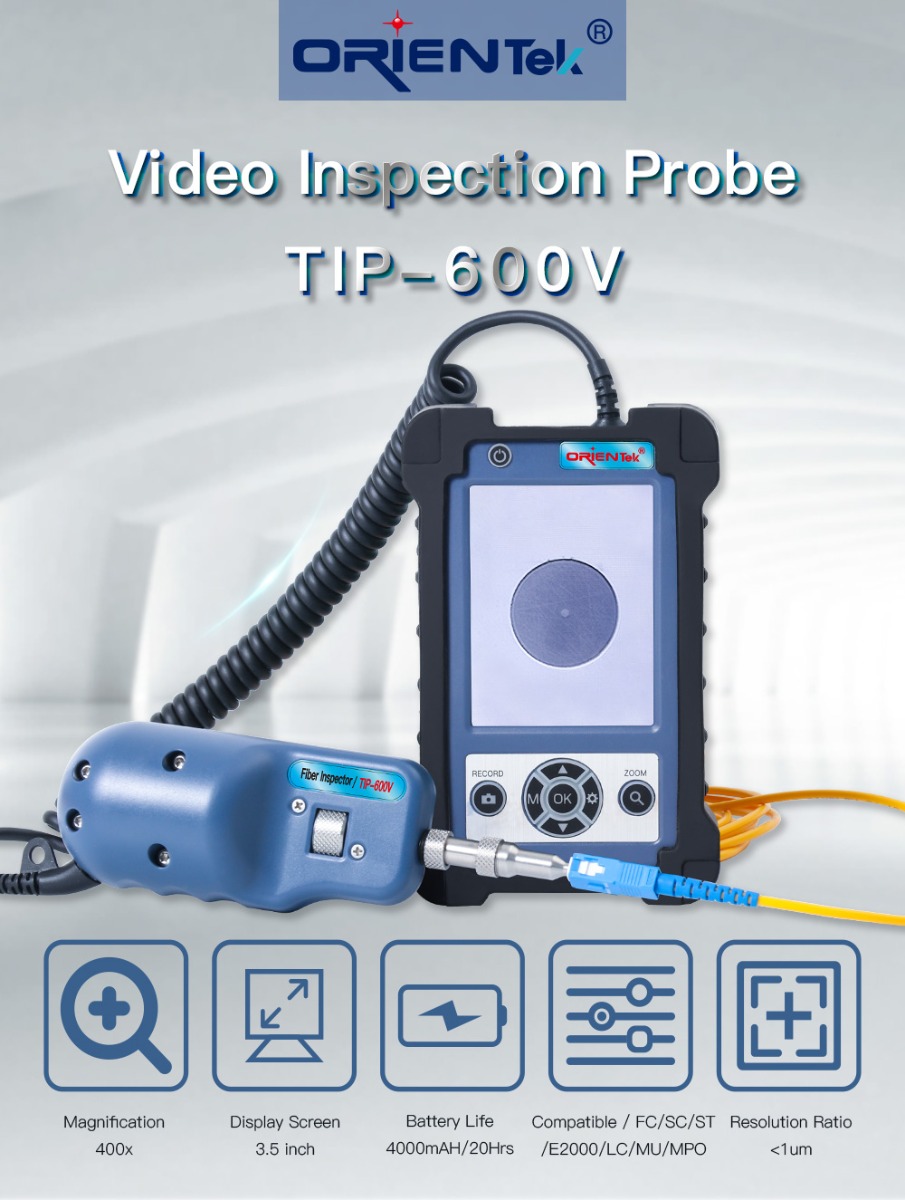

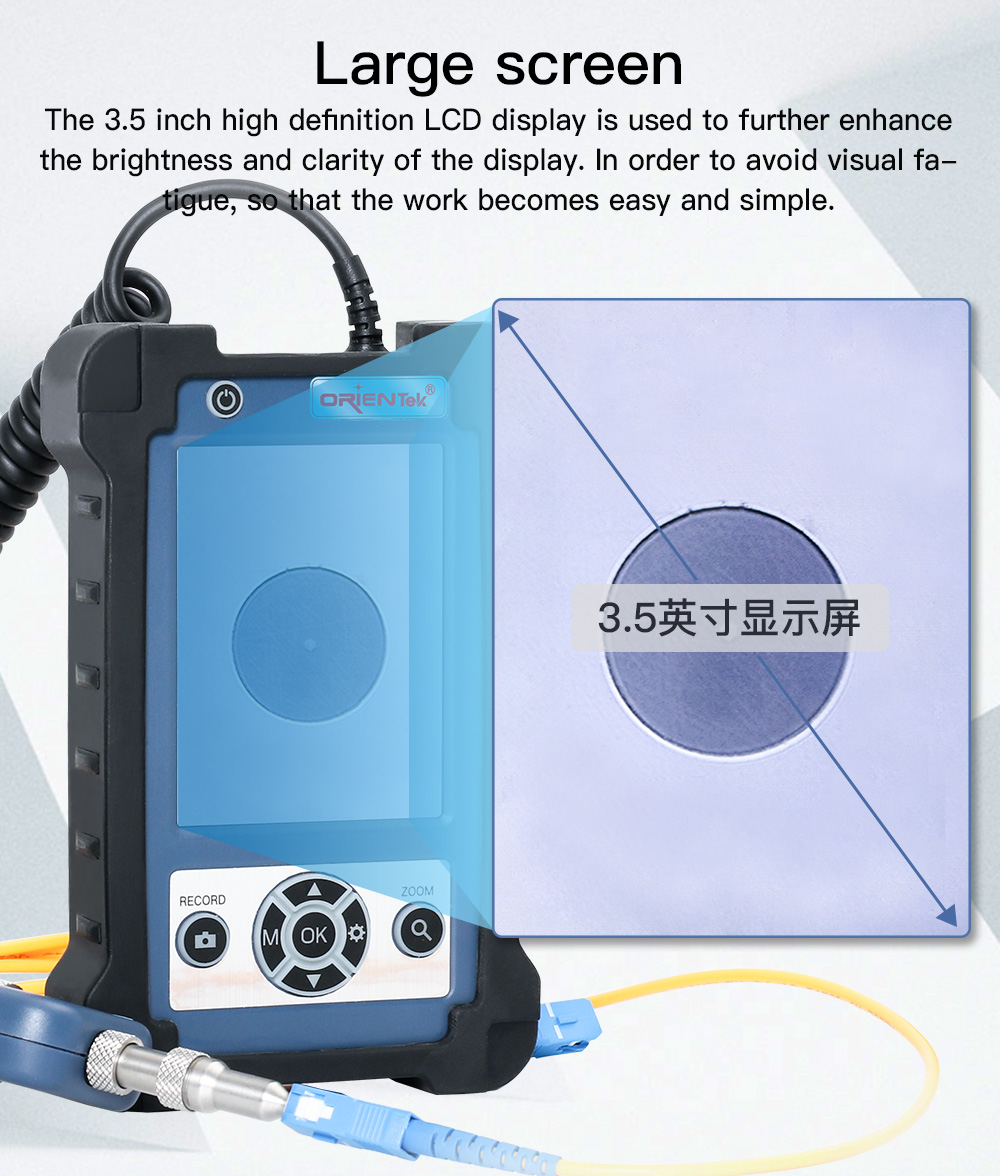

The 400x Fiber Optic Inspection Microscope is equipped with large capacity lithium-ion batteries with a capacity of up to 4000 mAh. Standby time is up to 20 hours, which is suitable for the needs of workers who go out for a long time.

The machine adopts micro USB interface, charging standard is 3.7V, charging is more convenient and simple.The angle of the bracket can be adjusted by rotation at will, which is stable and convenient. From the perspective of ergonomics, there is no need to watch on a single hand-held screen.In line with ergonomics, comfortable grip, compact, light and durable. Real-time video recording and expansion of TF card, convenient and fast recording of measurement information. Support data playback to facilitate inspection and data statistics.The panel design is concise, the operation is simple and practical, and the use is more humanized.