Types of Fusion Splicer Introduction More details please add official account: whatsapp/ skype +8613625297051

There are many types of fusion splicing machines available,varying from features, capability and cost. The following section elaborate details of several types of alignment fusion splicers.

CLAD ALIGNMENT

More basic fusion splicers employ clad alignments to line up the fibers for splicing. The fibers sit in a holder or V-groove and are lined up “physically”, based on the outer diameter of the fiber’s cladding. These splicing units are at the mercy of the fibers’ glass geometry characteristics and tolerances (Clad Diameter, Clad Non-Circularity, and Core-to-Clad Concentricity). Clad alignment splicers also have multiple cameras but only allow for single axis movement of the fiber. Alignment is aided by a fixed v-groove. The typical loss for this type of splice is 0.05dB.

OrienTek T49 Optical Fusion Splicer applies this method. With function of Active Clad-Alignment, Auto Splice and Auto Heat, this machine is much more cost-effective for many beloved customers(Only sale in USD 755).

CORE ALIGNMENT

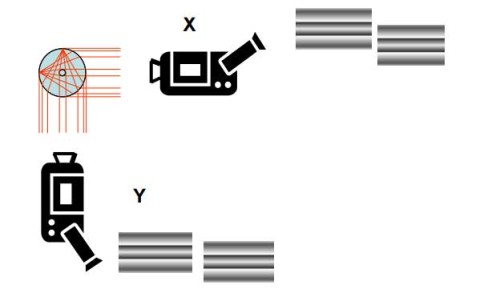

Optical fiber core alignment (also called “profile alignment”) fusion splicers use multiple cameras to inspect the two cleaved fibers before fusing and allow for multiple axis movement of the fibers. The two fibers are illuminated from two directions, 90 degrees apart. From the multiple video cameras, the machine recognizes the core of the fibers and aligns them automatically using movable stages.

Core alignment splicers are high-end units allow users to store separate programs or recipes where factors such as splice time and temperature can be highly customized. Such high end fusion splicers magnify and visually display the splice, and use active core-alignment to line up the fibers. Light injection technology and imaging software line up the fiber cores so maximum light passes from one fiber to the other, ensuring minimal splice loss.

This provides for precise fiber alignment, resulting in a typical splice loss of only 0.02dB. This level of precision is required for all single mode fiber applications and also enhances performance of multimode fiber. Ribbon splicers typically use core alignment.

Core alignment fusion splicers have long been the preferred method for CATV installations, backbone networks, specialty fiber applications, and optical components manufacturing largely because of their high accuracy and reliability.

Orientek T45 Fiber Optic core Alignment Fusion Splicer(USD 899) with fast splicing 7S and highly efficient heating 18S suitable for 0.25mm/0.9mm/3.0mm/flat/drop cable, whose average splicing loss reaches about 0.01dB.

FAQ for choose fusion splicer

Q: How to choose an ideal fusion splicer?

A: Except know the type of alignment, you may be aware of what’s your projected application area and what’s your budget. For instance, for many FTTX main line, it may be better to choose high precision machine with corQ: Which tye alignment and stable aerial operation design is much more popular. For those who hasn’t enough budget, it may be best to choose China fusion splicers like Orientek(T45 USD 899, T49 USD 755 )

Q: Which type Fiber Fusion Splicer welding speed is most fast.

A: Many splicers have fast speed, including Sumitomo type-82c+ splicing machine(USD 5299) embody with its 5s splicing, while its price is higher than some other brands. Komshine FX39(USD 1050), when it makes the propulsion, it needs 6s Splicing.

Q: which factor is crucial when choose fusion splicers?

A: Type of splicing fibers, alignment type, battery capacity and the cost all matter to choosing fusion splicing machine, for the reason of that some machines could execute single core cables instead of all types, battery capacity will affect the efficiency of working in the field if the power is running off, while the cost will directly control the budget of the project, so they are all crucial to the customers.

Conclusion

Despite the advances in fiber and fusion splicing technology, there are still many aspects of splicing of which practitioners must remain aware. Differences in fibers, equipment, environment and technique can yield different splice loss results. Understanding fusion splice process capability and splice loss measurement will help ensure that network owners, designers, contractors, and technicians have realistic expectations of splice loss.

Here are some guidelines for splicing contractors and technicians.

- Follow the applicable equipment manufacturer’s guidelines for setup and maintenance of all splice equipment. All fusion splicer have maintenance requirements which should be described in the operating manual. Besides cleaning regularly, they require electrode alignment and occasional replacement. Follow manufacturer’s requirements for servicing.

- Maintain clean equipment and a clean splice environment, being especially wary of windy and/or dusty conditions.

- Use the fusion splicer’s estimated splice loss reading as an initial go/no-go evaulation of the splice.

- Splice loss specifications should be set with the total link power budget in mind and be based on average splice loss.

More details please add official account: whatsapp/ skype +8613625297051