Fusion Splice vs. Mechanical Splice

Both fusion and mechanical splicing do the same thing - they connect the two fibers together and keep it in such a way that the light signals can be connected. In more detail, fusion is the point of attachment of two or more fibers that are fused together. This is achieved by a machine called a fusion splicer that performs two basic functions: aligning the fibers and melting them together, usually using an electric arc.

The mechanical splice is a simple alignment device that does not permanently connect the two fibers together and is designed to hold the ends of the two fibers in precise alignment so that light can pass from one fiber to another Root fiber.

Fusion stitching and mechanical stitching involve four basic steps. For the two methods, the first two steps are almost the same, and the last two steps are a little different.

Steps for Fusion Splice

Step 1: Fiber preparation. Fibers are prepared by stripping off all protective coatings (eg, cladding, jacket and sheath). Once only bare glass is left, the fibers are carefully cleaned - here, cleanliness is godliness.

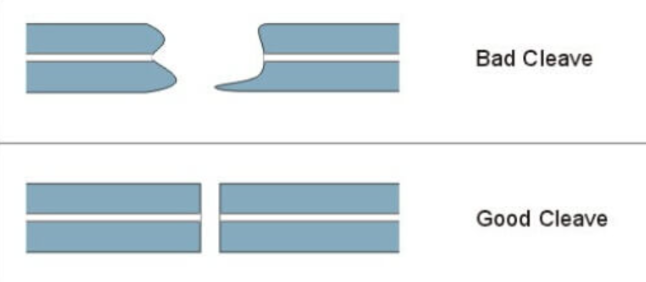

Step 2: Cleaving. The cutting end must be mirror smooth and perpendicular to the fiber axis for proper engagement.

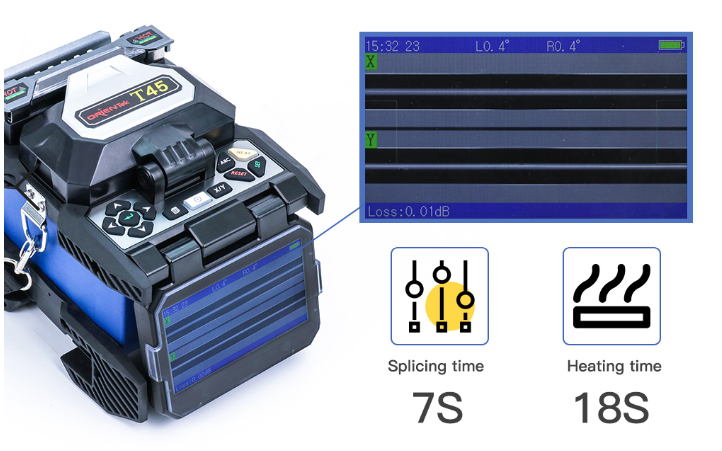

Step 3: Fusion fibers. In turn, fusion involves two steps: alignment and heating. The alignment can be fixed or three-dimensional, manual or automatic, and is typically done by means of an observer that amplifies or enhances the image of the end of the fiber so that they can be properly positioned. Common amplification devices are cameras, sight glasses and optical power meters. Aligning the fibers means perfectly matching their ends so that light can pass from one fiber to the other with minimal loss, reflection or distortion. Once the fibers are aligned, they are melted or burned together by creating a high voltage arc that melts the fiber tips and then pushes or feeds them together.

Step 4: Protect the fiber. Protecting the fiber from bending and stretching forces will ensure that the joint does not break during normal operation. A typical fusion splice has a tensile strength of 0.5 to 1.5 pounds and does not break during normal operation, but it is still necessary to prevent excessive bending and pulling forces. Using heat shrink tubing, silicone and/or mechanical crimp protectors protect the joint from external components and breakage.

Steps for Mechanical Splice

As mentioned earlier, the difference between the two lies in the last two steps. Therefore, steps 3 and 4 of the mechanical joint are described below.

Steps 1 and 2: View the process of welding.

Step 3: Mechanically connect the fibers. This method does not use heat. Simply place the fiber ends in the mechanical connector unit. The index matching gel within the mechanical splice device will help couple light from one fiber end to the other. Older devices will have an epoxy resin rather than an index matching gel that holds the core together.

Step 4: Protect the fiber. The complete mechanical joint provides the joint with its own protection.

For mechanical joints, the typical insertion loss (IL) is higher - between 0.2 dB and 0.75 dB. This is because the two fibers are simply aligned without a physical connection. (The insertion loss is due to the loss of signal power due to the insertion of the connector in the fiber.)

The fusion splice has lower insertion loss and better performance because the fusion splice provides a continuous connection between the two fibers. The typical loss of the splice joint is <0.1 dB to better prevent cable faults and weak signals.

Due to the investment required to add a fusion splicer to your kit, fusion splices typically have a higher initial investment, but they offer a lower cost per splice joint: $0.50 to $1.50 per joint.

Mechanical joints do not require a significant upfront investment in the tool, but the variable cost per joint is higher, at $10 to $30 per joint. The more splicing you perform, the lower the cost efficiency of the mechanical joint due to the variable cost per termination.

In conclusion

In general, the advantages of fusion splices are mainly lower loss and better reflection performance. It goes beyond mechanical joints in these areas. Many telecom and CATV companies are investing in splicing for their long-haul single-mode networks, but will still use mechanical splicing to shorten local cable runs. Because analog video signals require minimal reflection for optimum performance, fusion splices are also preferred for this application. The LAN industry can choose any method because signal loss and reflection are secondary issues for most LAN applications