We all know that fiber fiber measuring is not only a test of practical ability, but also a test of carefulness and patience. It is often necessary to change the fiber splicing location according to the actual needs. Whether it is beside the cable well under the hot sun, or on the dim and cold basement. Communicators need to overcome the influence of unfavorable factors such as weather and environment, conduct thorough consideration and consider and Standardize operations and complete the molten fiber mission.

However, when the optical cable line that needs to repair the high -altitude rack is needed, we need to repair quickly for users, but what should we do? According to conventional ideas, we will choose to splice fiber on the ground, or install the metal bracket to the coil before each high -altitude operation, but this is obviously a low -efficiency method ↓↓↓

So is there any way to complete the high -altitude melt fiber efficient and high quality? In order to adapt to various difficult outdoor construction environments such as high-altitude fiber splicing, Orientek has developed a high-quality, economical, practical, compact and portable optical fiber fusion splicer to liberate the hands of the communicator--T49 Mini FTTx optical fiber fusion splicer.

The leader of high-altitude work

If you want to climb high, you must first light yourself. The Orientek T49 adopts a mini palm-shaped design and weighs only 1.35kg including the battery. The user can easily hold the machine with one hand. Compared with the bulky and heavy-duty large-volume fusion splicer, it is more flexible; the T49 is small but delicate, the well-designed fresh and natural green is visually comfortable, and the finely polished shell makes the fuselage have a good touch.

T49 provides customers with the multi-functional carrying bag shown in the picture above. The carrying bag with special rainproof design is very light. The carrying bag has a cushion inside and a hard top cover, which is used as a platform for placing the welding machine. The rope is used to secure the fusion splicer. Tie a wide adjustable length rope to both ends of the carrying bag, wrap it around the neck, and then use another wide rope to fix the carrying bag to the waist, and a simple aerial work platform is formed.

Space saving for ground work

The main workflow of fiber splicing is cutting, hot-melting, and cooling. In daily work, we cannot predict what kind of working environment the next project will face: narrow passages, muddy mountain roads, and uneven ground. It is specially designed for communicators with narrow operating space and limited operating platform--the operating bracket of the optical fiber fusion splicer is very necessary.

This operating bracket is a specially designed base specification according to the screw hole spacing on the rear of the T49 body; the base is fixed on the fusion splicer by screws to achieve a stable and firm installation effect; the user can adjust the height of the bracket independently, and screw it by hand to fix it;

By adjusting the top screw, the operating platform can be adapted to various types of cutting knives; the individually designed cooling tray is fixed by magnetic attraction, which is convenient for users to take at any time.

The operation bracket concentrates the entire workflow in the same operation space, making the entire work flow like flowing water, which can greatly improve the work efficiency of front-line operations. Isn’t it very considerate?

Tool-less electrode replacement

T49 also adopts an innovative electrode design, adding a new layer of "armor" to the electrode rod. The new appearance design, fully transparent material, the internal structure of the electrode is clear at a glance, even if it is ultra-small, it is not lacking in rich shapes. Users do not need tools, they can replace the electrode rods immediately by turning the screw by hand. Novices can use T49 without pressure. The electrode life is up to 5000 times (replaceable), which not only greatly saves work time, but also saves project costs!

Excellent fiber fusion performance

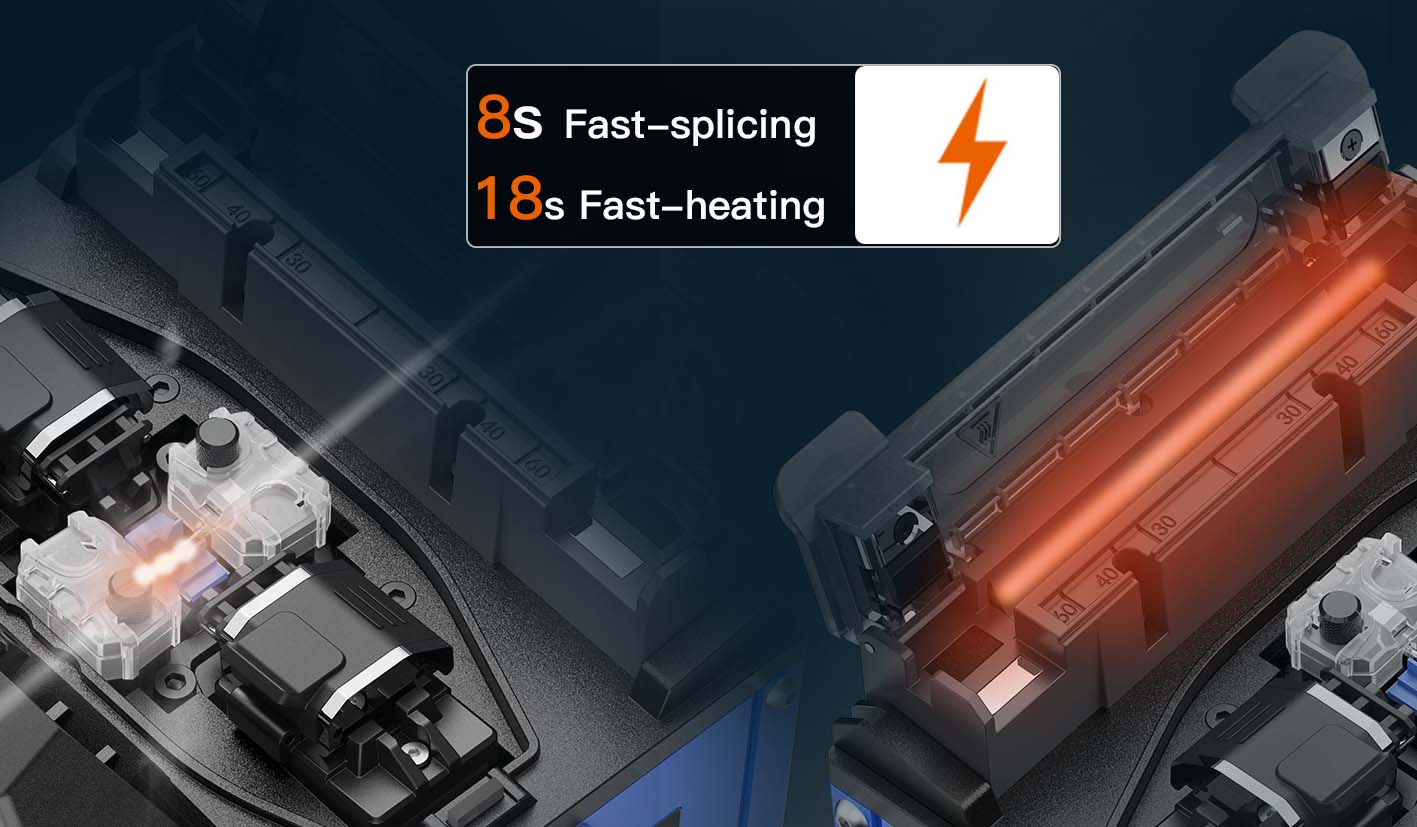

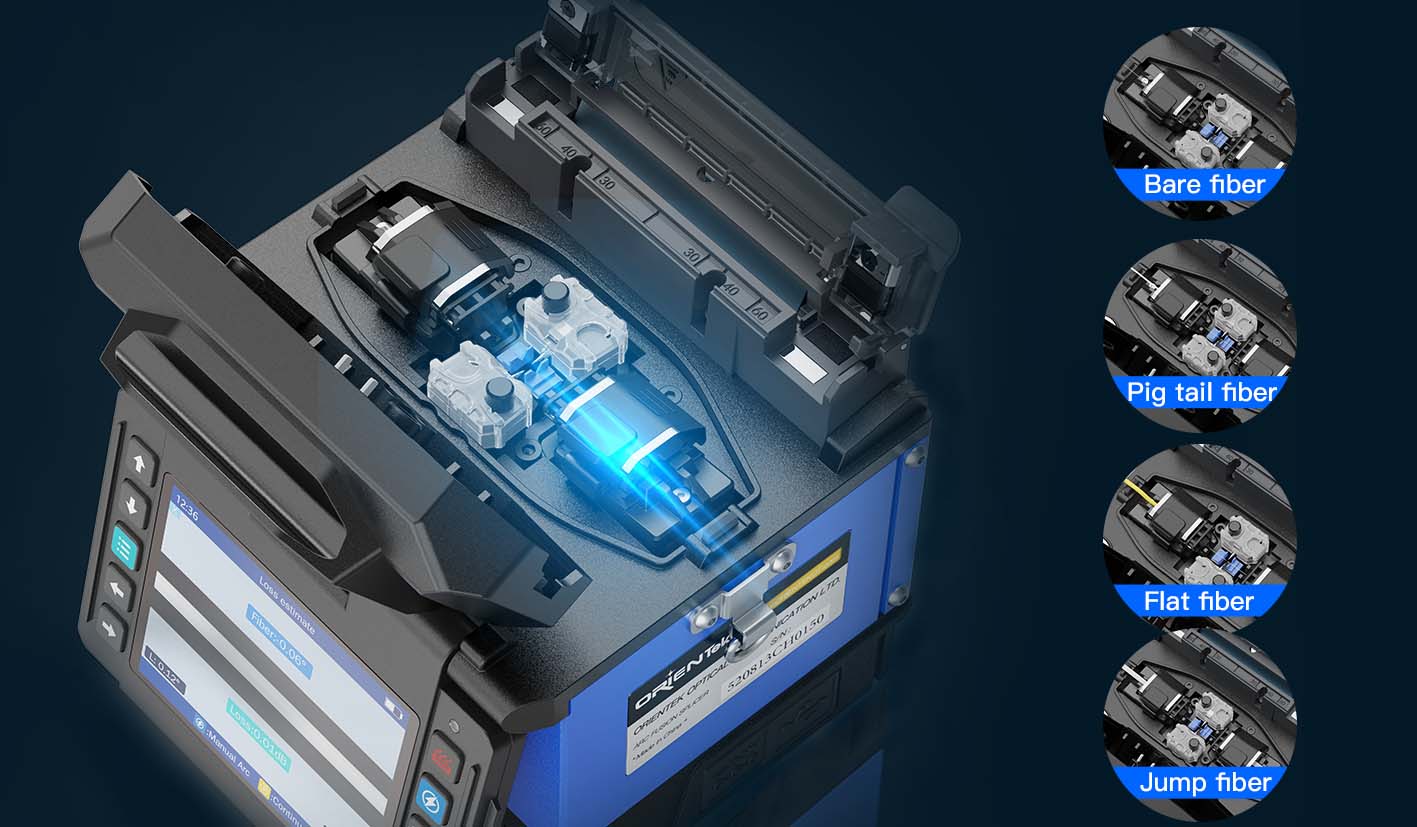

In addition to its excellent hardware structure, T49 is not inferior to any small leather cord machine in terms of fiber fusion performance! Orientek T49 Mini optical fiber fusion splicer has built-in four motors, which can realize 8S automatic splicing, 18S automatic heating, and the typical splicing loss is 0.01dB, realizing the double improvement of working speed and quality.

In addition, T49 is also equipped with a three-in-one fixture, which is compatible with various types of optical fibers, suitable for leather cables, patch cords, pigtails, and bare fibers, with strong usability; 3400mAh lithium battery can support 120 times of splicing & heating.

Warranty for three years

- We, Orientek, do hereby warrant our Fusion splicer、OTDR、Test & Measurement、Tool、Fiber Optic Cleaning products, be free from defects due to defective materials or workmanship for a period of 3 years from the date of shipment.

- We, Orientek, do hereby warrant our accessories such as Battery, Cleaver, Thermal Stripper, AC adapter, Screen, Heater, Carry Casewhich are included in the standard package of Fusion Splicer, OTDR products, be free from defects due to defective materials or workmanship for a period of 1 year from the date of shipment.

T49 is a practical economy FTTX fiber fiber fiber fiber fiber fiber built by Orientek for the majority of communicators to flexibly adapt to the operating environment. The T49 can solve the problem of high -altitude operation tools to be available, splice fiber such as high altitude, adapt to various narrow construction spaces. It also has the advantages of saving manpower and material resources, long available cycles, and small use difficulty, which is convenient for front -line communication workers to work.