Fiber damage, optical loss doubled for no reason - you must know these operating points

Fiber optic operation, from the point of view is meticulous, because every data will form a judgment, no matter for technical experts or newcomers just in, after every seemingly ordinary operation, it is inevitable that some conditions.

For example, in the process of fiber inspection, the loss of light is doubled for no reason, and even the optical signal is blocked. After verification, it is known that particles and dirt that are invisible to the naked eye are distributed on the end face of the fiber. Such dirt not only blocks the signal, but also causes the reflected wave to cause different degrees of damage to the fiber. There is data showing that the network connection failed, 85% is due to the port is dirty when connected.

In the high power state, this situation will get worse, because the peak power of the input filter is large and the fiber head is not clean, so that the fiber core is damaged, and slight dust can cause the core to burn out. If the core burns out, it will not only increase the working cost of the fiber, but also make the situation more complicated.

Therefore, before the operation, we must ensure that the fiber end face is clean, and the cleanness of the fiber end is the same as that of daily understanding. We know that the fiber end face is “looking” and the end face is enlarged. Ten times, a hundred times, it is completely another concept.

First of all, you have to tell if there is dirt on the end face

Recommended Otientek handheld fiber end face magnifier, this magnifying glass can achieve up to 400 times magnification, the actual 200 times and 400 times can be selected, the operation is also very simple, after inserting the end face, through the hand wheel focusing, you can light Easy to understand the situation of the end face. The design also pays attention to ergonomics, and the lightweight shape makes it just right when it is held.

OrienTek Video Inspection Probe TIS-200▴

In terms of design, excellence, this product is very precise, using imported lenses, so you can ensure the clarity of the picture when viewing, while the center of the fiber end is very good, suitable for PC end face, The APC end face is detected.

For many people, the magnifying glass is good, but it can only see the particles more clearly. After all, it is not straightforward. Then Jixing's fiber end face detector is suitable. It can directly reflect the dirt on the end face, 400 times. Zoom in to make the end condition clear at a glance. The recognition accuracy of the product is less than 1μm, which can be said to be very reliable.

The product design uses a 3.5-inch high-definition LCD display to further enhance the brightness and clarity of the display, avoiding visual fatigue and making work easier. At the same time, support a variety of fiber optic connectors - FC, SC, ST, LC, for the SC female, LC female can also be plug and test, very easy and convenient, suitable for many occasions.

Orientek Vide Inspection Probe TIP-600▴

After the test, the result of this test is hard to remember by memory alone, especially in the case of many port detections. To this end, in our products, the real-time video and extended TF card is added. Its function is to record the detection in real time, and it can support data playback, which is convenient for post-checking and data statistics.

Introduced so many instruments about port detection, I believe that everyone has chosen the instrument for detecting the port. After the test is finished, the next thing to do is to clean the work.

Speaking of cleaning fiber,

It’s actually a very professional job.

If so

Not only does it not clean the port, but it also adds more dirt to the port. The usual soft cloth, wiped rag, the dirt on it is very much. Therefore, the cleaning port needs professional products to handle the dirt of the port.

Fiber optic end-face connector cleaning ▴

Orientek end-face cleaning paper solves this problem very well. This product is made of professional dust-free and lint-free cloth material. It will not be stained with any ordinary wiping paper when it is wiped. Cause secondary pollution.

In design, the unique embossing process can bring a certain buffer and protect the port. The rubber pad with high wear resistance and high elasticity is adopted, which can effectively prevent the end surface from being scratched, and is more convenient to operate.

In fiber optic operation, there are many usage scenarios that can contaminate a lot of dust and dirt. Not only the end face, like bare fiber, the screen of the device will have particles. Jixing's cylindrical fiber-optic cleaning paper is an essential accessory for daily operation. The cylinder design makes it easy to pull and can be operated with one hand. The imported dust-free and non-woven paper can clean the valuable equipment like the fusion splicer.

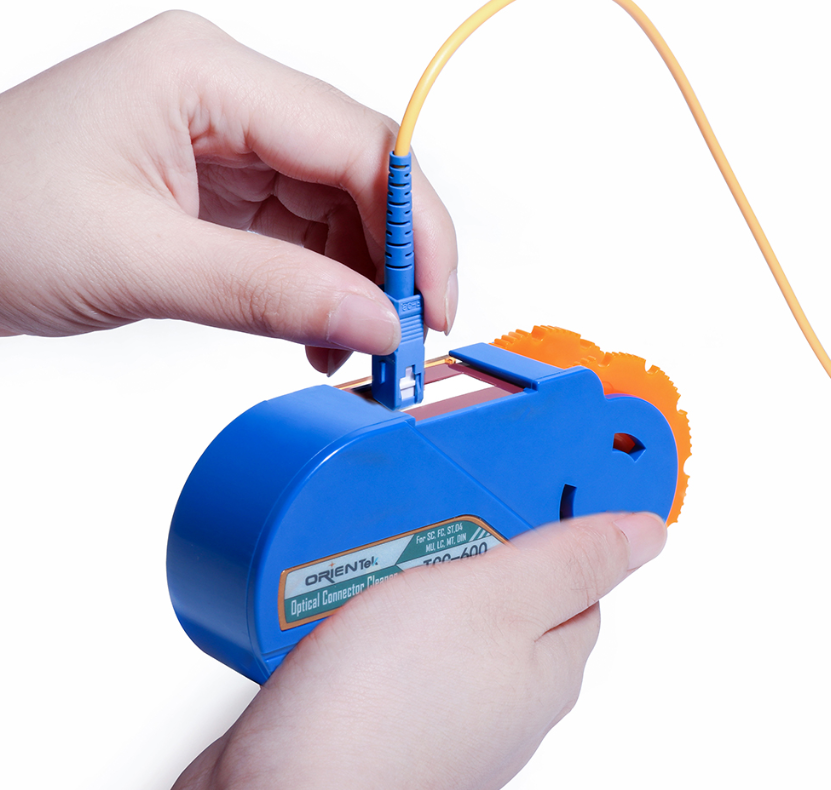

The cleaning of the fiber end face seems to be simple, but it requires careful operation to be clean and effortless. The following cleaning product, the OrienTek cassette fiber end-face cleaning box, uses a tape-type design, which can be cleaned by simply wiping the fiber ferrule on the cleaning tape a few times.

The material is made of high-density textile fiber, which can’t be static electricity, no hair removal, and no need to add alcohol during operation. Its clean mouth and cover cover design is very intimate, can be gently closed after we use, to avoid secondary pollution of the surface of the cleaning paper.

Open the cleaning box, we can see that the product is like a tape for playing music. It is designed to be easily replaced with a core later.

Generally, after using more than 500 times, you can use it again after changing the cleaning core. It can be said that it is very cost effective.

In addition to the same cleaning efficiency and cleaning function as the previous products, the cleaning paper that has been wiped over can be turned to the other side by rotating the yellow gear to expose the clean cleaning paper. The lightweight shape allows you to guess the amount of cleaning paper at any time, and the replaceable cleaning core can also help you save a lot of money.

The cleaning of the fiber end face does not seem to be important. In fact, it will cause no small interference to our fiber work. For this reason, we must pay attention to the inspection of the end face and timely clean the fiber end face.